Why Insulated Floor Panels Matter for Your Home’s Comfort and Efficiency

An insulated floor panel is a pre-manufactured building component that combines structural flooring with built-in thermal insulation. Featuring a foam core between structural layers, these panels provide continuous insulation that can prevent up to 15% of a home’s heat loss through the floor. They are an ideal solution for basements, garages, and slab-on-grade homes, creating warmer, drier, and more energy-efficient living spaces. Key features include continuous R-values, fast installation, moisture protection, and a high load capacity.

If you’re dealing with cold floors, high heating bills, or musty lower-level rooms, the cause is often heat escaping through uninsulated concrete. For homeowners in Santa Rosa, CA, committed to sustainability, understanding the importance of sustainable insulation is key. Traditional floors are thermal weak points, but insulated panels create a continuous thermal break, stopping heat loss while providing a stable base for finished flooring. Ready to improve your home’s efficiency? Contact Sustainable Living Builders to learn more.

What is an Insulated Floor Panel and How Does It Work?

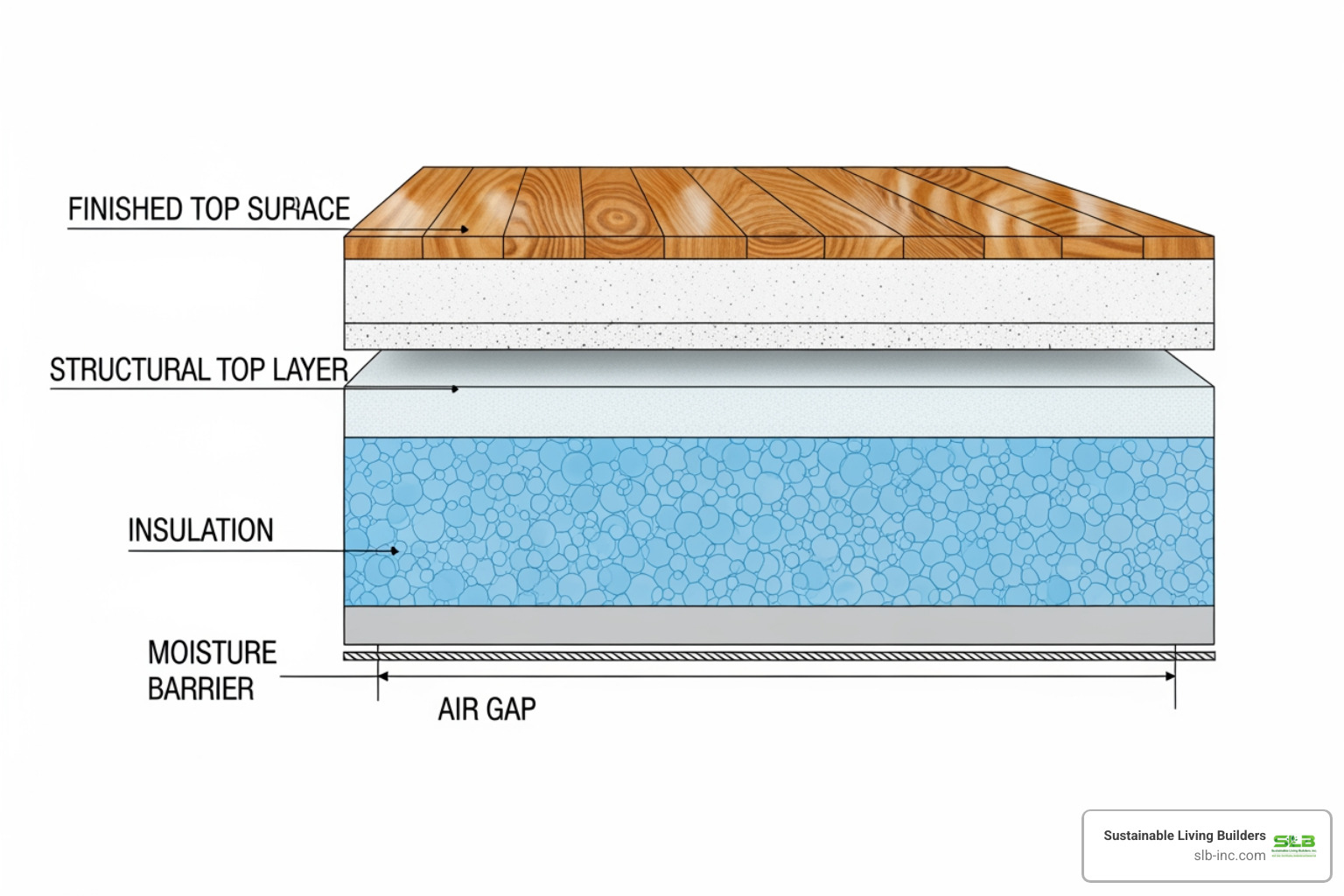

An insulated floor panel is a smart, composite building material that provides a solid structural base for flooring while acting as a thermal barrier. The magic is in its layers: a robust top surface, an insulating foam core, and often a moisture barrier or air gap at the bottom. Together, these layers create a “thermal break,” interrupting the path heat takes to escape into the cold ground.

This is crucial because heat naturally flows from warm to cold areas. With an uninsulated floor, your heating system constantly battles heat loss, as warmth seeps into the ground. Studies show up to 15% of a home’s heat can escape through an uninsulated floor. Insulated floor panels solve this with “continuous insulation,” an unbroken barrier that eliminates the thermal bridges found in older construction methods. The result is warmer floors, a more efficient heating system, and lower energy bills. An energy audit service can identify these hidden inefficiencies in your home.

Common Types of Insulated Floor Panels

Several types of insulated floor panels are available, each suited for different applications.

- Structural Insulated Panels (SIPs): These heavy-duty panels sandwich a foam core between two structural facings like OSB. Incredibly strong and highly insulating, SIPs are ideal for new construction and major additions, drastically reducing build time.

- Interlocking foam panels: A DIY-friendly option, these panels click together and often include air gap technology. This small, raised space allows moisture to evaporate, preventing mold and musty smells, making them perfect for basement projects.

- Modular subfloor systems: Similar to interlocking panels, these systems emphasize a raised design to create an air gap for superior moisture management and airflow.

- Radiant heat panels: These specialized panels have pre-cut grooves to hold hydronic tubing or electric heating cables, simplifying the installation of radiant floor heating and directing warmth upward into the room.

Understanding these options is the first step toward making foolproof choices for every sustainable living home.

Core Insulation Materials: EPS vs. XPS

When choosing insulated floor panels, you’ll encounter two main foam types: EPS and XPS. Both are polystyrene, but their long-term performance differs.

Expanded Polystyrene (EPS) is the common, affordable choice. Its key strength is long-term R-value stability. Studies show EPS retains about 94% of its insulating power, losing only around 6% of its R-value over its lifetime.

Extruded Polystyrene (XPS) is the pink, blue, or green foam board with a smooth surface. It has higher compressive strength and moisture resistance. However, research shows XPS can lose nearly 48% of its R-value as it ages. This means you might need twice the thickness of XPS to get the same long-term performance as EPS.

Here’s a comparison of these key differences:

| Feature | Expanded Polystyrene (EPS) | Extruded Polystyrene (XPS) |

|---|---|---|

| Heat Retention Factor | 94% | 52% |

| Long-term R-value Loss | ~6% | ~48% |

| Moisture Resistance | Good, but can absorb some moisture if continuously exposed | Excellent, highly resistant to moisture absorption |

| Compressive Strength | Good | Very Good |

| Typical Appearance | White, beaded | Pink, blue, or green; smooth surface |

For homeowners in California, this distinction is vital. An insulated floor panel with an EPS core offers more reliable long-term performance, aligning with a sustainable approach to building.

Key Benefits for Your Home and Wallet

Installing insulated floor panels offers benefits beyond energy savings, improving your home’s comfort, health, and value. The most immediate change is comfort—no more cold floors in your basement or on your ground floor. By creating a thermal barrier, these panels keep your living space cozy and inviting.

This comfort translates to financial savings. By preventing up to 15% of heat loss through the floor, the panels reduce the workload on your heating system, lowering your monthly energy bills. For those who believe sustainable living starts at home, this is a practical way to merge values with savings. Additionally, the panels offer crucial moisture protection, often using air gap technology to prevent dampness and mold growth. A bonus benefit is sound dampening, as the foam core absorbs impact noise, making rooms quieter.

Long-Term Durability and Performance

Insulated floor panels improve your home’s long-term durability. By managing moisture and temperature, they protect finished flooring like laminate or hardwood from warping and degradation. These systems are also incredibly strong, with many supporting loads over 3,000 pounds per square foot—enough for home gyms or heavy furniture. Unlike wood, the engineered components resist rot and decay. When you choose panels with stable insulation like EPS, which retains 94% of its R-value, you ensure consistent energy savings and comfort for decades. This aligns with the philosophy behind other long-term solutions like the advantages of sustainable roofing.

Creating a Healthier Indoor Environment

These panels significantly improve indoor air quality, particularly in basements. Many systems feature air gap technology, creating a small space between the concrete and the panel. Concrete is porous and releases moisture; this air gap allows that moisture to evaporate and vent out, preventing the dampness that leads to musty odors, mold, and mildew. By managing moisture at the source, the panels keep your space fresh and reduce allergens. This focus on a healthy living space is a core part of creating sustainable homes and complements initiatives like home electrification.

Selecting the Perfect Panels: What to Look For

When selecting an insulated floor panel, focus on a few key factors. The R-value is paramount; look for the continuous R-value, which measures performance across the entire panel. Also, consider the panel’s thickness, as it will impact your room’s final ceiling height. The material composition is critical for long-term performance; EPS foam, for example, retains its R-value better over time than XPS. Finally, check the load capacity to ensure it can support your planned use and look for a smart interlocking design for faster, more secure installation. These details are central to the guide to sustainable building practices: strategies & trends.

Common Applications for Insulated Floor Panels

The versatility of insulated floor panels makes them suitable for numerous applications in homes across Sonoma, Marin, and Napa Counties.

- Basements: Panels transform cold, damp basements into warm, dry, and usable living areas.

- Garage conversions: A popular choice for creating home gyms or studios, panels can make a concrete garage floor feel significantly warmer.

- Slab-on-grade homes: Installing panels over a concrete slab foundation makes the entire home feel cozier and more energy-efficient.

- New construction and retrofits: Incorporating panels from the start is a smart investment, but they are also highly effective in retrofits, especially in rooms over unheated crawl spaces.

Our expertise in insulation installation in Santa Rosa, CA can help you find the perfect solution for your project.

Building Codes and Certifications

Any insulated floor panel project must meet local building codes. California codes specify minimum insulation levels for floors, which vary by climate zone. Our team is familiar with the requirements in Sonoma, Marin, and Napa Counties and ensures every installation is compliant. For commercial use, such as in walk-in coolers, panels must meet strict NSF certifications to ensure food safety and prevent structural issues like frost heaving. You can learn more about these standards at NSF certifications. Meeting these requirements is essential for a safe, durable, and compliant project.

Installation and Maintenance Guide

One of the most attractive features of modern insulated floor panel systems is their straightforward, DIY-friendly installation. Some systems can be installed up to four times faster than traditional subflooring, allowing a 500-square-foot room to be completed in an afternoon. Once installed, maintenance is minimal. The engineered materials resist moisture and decay, providing reliable performance for years without constant upkeep.

Best Practices for a Flawless Insulated Floor Panel Installation

Proper installation ensures decades of performance. Follow these best practices for a flawless result:

- Surface Preparation: The concrete slab must be clean, dry, and free of debris, old adhesives, or paint.

- Leveling: Use leveling shims for minor imperfections (under 1/4 inch). For larger dips, apply a self-leveling compound to create a smooth surface.

- Moisture Check: Use a moisture meter to determine if additional waterproofing is needed before you begin.

- Installation Method: Most systems use a floating installation. However, depending on the product and finished flooring, panels may need to be glued or screwed to the concrete.

- Perimeter Gaps: Leave a quarter-inch expansion gap around the room’s perimeter. This is crucial for air circulation and moisture evaporation—do not seal it.

- Headroom: Measure your ceiling height carefully. Panels add height, which could affect door clearances.

- Essential Tools: You’ll need basic tools like a measuring tape, saw, level, rubber mallet, and spacers.

Compatibility with Flooring and Heating Systems

Once installed, your insulated floor panel system provides a stable foundation for nearly any finished flooring. It’s compatible with laminate, LVT/LVP, carpet, engineered hardwood, and ceramic or porcelain tile. For tile or when using a power carpet stretcher, fastening the panels to the concrete is often recommended.

These panels are also highly compatible with radiant floor heating systems. For maximum efficiency, install the heating system on top of the insulated panels. This directs all the warmth upward into your living space. Some panels even come with pre-cut grooves for hydronic tubing, simplifying installation and creating an exceptionally comfortable and energy-efficient floor.

Frequently Asked Questions about Insulated Floor Panels

We’ve worked with many homeowners in Santa Rosa and Sonoma County, and we’ve compiled answers to the most common questions about insulated floor panels.

Can insulated floor panels be installed over uneven concrete?

Yes, these panels are designed to work on concrete that isn’t perfectly flat. For minor variations of less than 1/4 inch, you can use leveling shims under the panels to create a stable surface. If your concrete has more significant dips or humps (greater than 1/4 inch), it’s best to first apply a self-leveling compound. Proper surface preparation is the key to a successful, long-lasting installation.

Can I install radiant heating with these panels?

Absolutely. Insulated floor panel systems are an excellent partner for both hydronic and electric radiant floor heating. For the best performance, the heating system should be installed on top of the insulated panels. This ensures the insulation directs all the warmth upward into your room, rather than letting it escape into the cold concrete slab below. Some panels even have pre-grooved channels to simplify the installation of hydronic tubing.

How much weight can insulated floor panels support?

High-quality insulated floor panels are engineered for impressive strength. Most products are rated to support over 3,000 pounds per square foot, with some systems handling as much as 3,650 lbs./sq. ft. This means you can confidently place heavy furniture, pool tables, or home gym equipment on your new floor without concern. Always check the manufacturer’s specifications for the specific product you choose, but rest assured that these panels are built to handle real-world loads.

Conclusion

If you’re tired of cold floors, high heating bills, and musty basements, insulated floor panels offer a complete solution. By creating a continuous thermal barrier, they improve comfort, boost energy efficiency, and provide crucial moisture protection all at once. This innovative system lowers your carbon footprint and protects your finished flooring from dampness, while air gap technology keeps your lower-level rooms fresh and healthy.

At Sustainable Living Builders, we’ve seen how a properly insulated foundation can transform homes across Santa Rosa and the surrounding counties. We take a holistic approach, integrating solutions like insulated floor panels to build healthier, more sustainable living spaces that provide years of comfort and performance.

Ready to upgrade your home’s comfort and efficiency? Explore our sustainable property solutions and the comprehensive services we provide to take the first step toward a better home.